What the Chip Shortage Means

Your car needs repairing but what do you do? In days of old a repair facility will diagnose and find the problem. If a replacement part is required, they will order it from any number of suppliers that manufacture vehicle modules. But in times of the pandemic and the global supply chain shortages - this is no longer an easy task.

The chip supply is still catching up with demand and car makers are looking at means to reduce their reliance on semiconductors. Either by re-designing vehicles to have fewer modules, or by warning customers that if they want their car, they can have it without some features.

Major car features including park assist, advanced driver assist, and infotainment extras may be excluded from the vehicle - even when their VIN and order from the factory has them included. This means auto repair shops need to do some detective work to understand what features their customers' cars have.

Everyday electronics in recent years have incorporated ‘smart’ technology. Meaning they use multiple chips to process and handle data. Car makers are competing with this industry too. Resulting in an even greater demand, with short supply from Russia’s invasion of Ukraine, halting major production in eastern European areas.

Vehicles are commonly fitted with at least 1,000 semiconductor chips. They control anything from interior lighting, battery management, sensors for temperature, pressure and humidity, fuel, and liquid level, ADAS modules and much more.

The latest bans on internal combustion engine vehicles in the likes of California and across Europe is coming into play after 2035. With automakers increasing their EV lineup, this trend towards electric cars will only continue to increase.

The C.A.S.E or “Connectivity, ADAS, Sharing and Electrification” are the core trends we are seeing in the industry. All of which require semiconductors. In 2020, this market was a $73bn industry. With an estimated 14.75% growth rate per year, the industry is set to double in 2026 to $147bn and reach to a $318bn industry by 2035. The chart below shows the heavy growth as cited in Automotive Semiconductor Trends 2021.

Figure 1 - Automotive Semiconductor Industry Size

How it affects Auto Repair Shops

All aspects of the repair process are already or will soon be affected as a result of the chip shortages. With inflation at an already high rate, estimating will need to be adjusted, as well as finding the correct parts on the vehicle, and the plan for repair afterwards.

For example, repair shops need to do an additional checking process with the dealer to confirm that the car was actually shipped with the module that is stated on the VIN checks, as a result of the global chip supply shortage. A Body Control Module (BCM), ABS Brake Module, Powertrain Control Module (PCM) and Engine Control Module (ECM) all incorporate semiconductor chips. Causing a delay in sourcing parts if repair shops use traditional methods.

Database Enhancement Gateway (DEG) Administrator, Danny Gredinberg says that “Extra time upfront spent is always going to be the saving grace because there’s nothing worse than waiting two or three weeks for your part to finally show up and then it’s the wrong part.” A lot of due diligence is needed to identify and repair a module.

Gladney Automotive Solutions CEO, Kirk Gladney Holland says that “accurate information is a must for an automotive diagnostician when determining the correct failure. Putting the customer's transportation needs first, while seeking the highest value for each client and their vehicle is key.”

With the client waiting potentially months for new service parts, it’s extremely important the right module is found in the right time frame. Technicians and estimators can’t assume that a feature they would normally associate with a particular trim level will be included in the car they are repairing. Throwing the calibration of odometers, and other repair processes out of the window. This forces repair shops to re-think their repairing methods. Luckily there are ways around replacing new-for-old modules.

The New Way of Sourcing Replacement Parts

As an alternative to ordering a new module from the OEM, your faulty TCM, Radio, EPS and more can now be repaired by experts in the field such as Gladney Automotive Solutions .

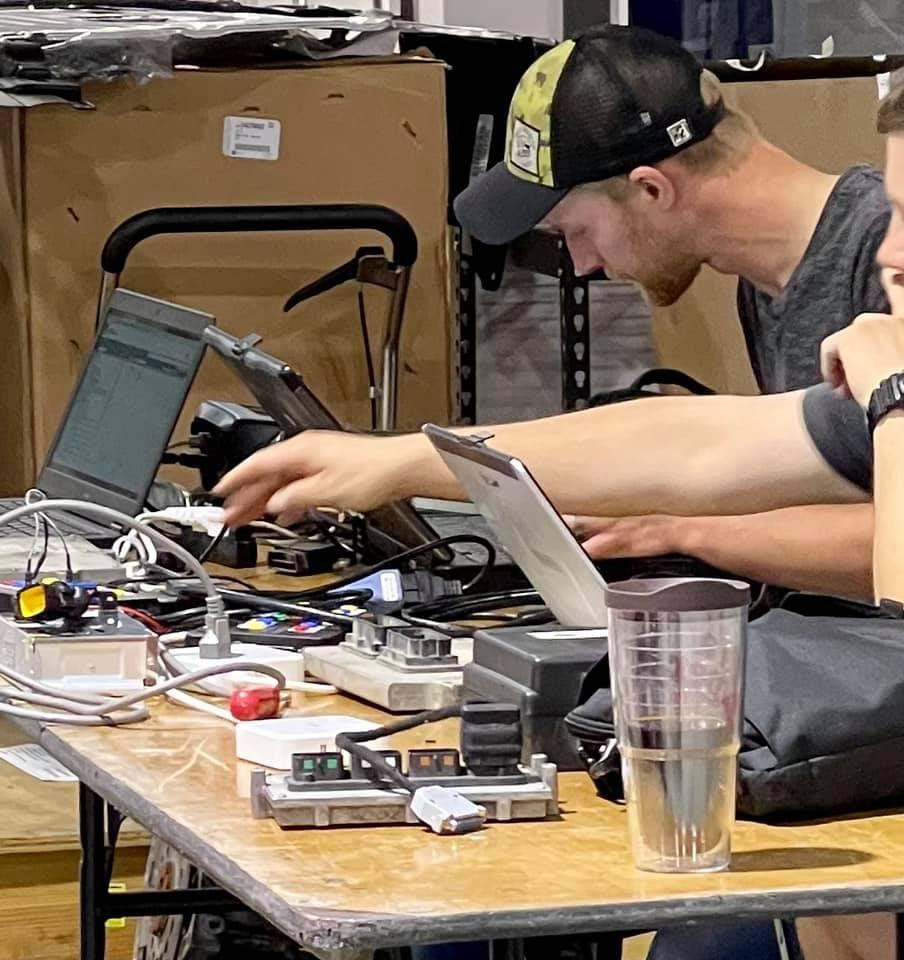

Using companies such as Gladney Automotive Solutions in College Station, who dismantle and diagnose faults on your existing module are vital in reducing costs and turnaround time for repair shops.

This method of automotive module repair is a great way to tackle chip shortages and can save you as the repair shop on both time and resources. Not only are they recycling existing components, but they also reduce the need to source new parts and wait times for them to be available.

All without hugely inflated prices of a new module, which has appeared as a result of the chip shortage.

They also specialize in a range of modules including ABS, BCM, JBE, TIPM, Chassis, Powertrain, and Transmission.

With a host of programming and repairs, Gladney Automotive Solutions can program keys, deal with transponders, and provide a number of cluster repairs including odometer correction. As well as ECU flashing, programming, and repairing.

They have a handy catalog of modules which are repairable. Simple list your vehicle V.I.N. Number and provide the specific module you need repairing. Matching up part number and model year is vital at this stage.

Not only for cars, they also service modules for RVs, Medium Duty Trucks and ATVs.

It's important to note that not every unit is repairable. If the PCB is burned out, if it has evidence of water ingress, or if components are hardwired in and cannot be replaced. If this is the case with your unit, they will recommend a remanufactured control unit instead.

Being safe knowing that it is being repaired by certified technicians with over 40 years’ combined experience in this space and over 1,000 certified reviews.

They also offer limited mobile services such as new PCM, BCM, ABS, TCM coding, including a long list of used module programming and data correction services that dealers would otherwise not touch.

How It Works

Once you have found the part you need repairing, make sure the description matches the fault you have on your customer's vehicle, and place the order.

Simply complete the Control Module Information form Control Module Info Form (Required) and upload a copy here Contact w/ File Share .

Once ready and removed from the vehicle, secure your module in a package and send them your faulty unit Shipping & Location.

Upon receiving they will perform a Diagnostic Evaluation Service (DES) to work out what is faulty, and if it can be repaired.

Gladney Automotive Solutions always aims to fix the module right away.

If required Gladney Automotive Solutions will source the sub-components as needed and will go ahead and repair the module. Gladney Automotive Solutions will retest the unit before sending it back to the repair shop.

Then simply re-install into the vehicle, following any added instructions they provide. Then the car is ready, meaning you are back on the road in no time!

How Gladney Can Help

Knowing all there is to know in the auto repair world. Gladney Automotive Solutions and staff have decades of experience and are constantly looking at trends and news in the industry of auto repair.

Specializing in all aspects of car repair including wire harness repair, module repair, diagnostics, ADAS calibrations, electrical vehicle service, automotive keys and so much more. Get in touch today for a quote! Contact Us

Conclusion

The semiconductor shortage has been boosted recently with the CHIPS and Science Act here in the US. Promising over $50bn of investment to domestically manufacture and research semiconductor chips for the local market which will help boost capacity, coping with demand. Although this act will inject investment, it will still take a number of years to build and start producing new chips - meaning the shortage is here to stay for a while at least.

Luckily, there are a number of important businesses that aim to repair existing car parts and modules without needing to rely on new chips. Leading the way in advanced repairs, Gladney Automotive Solutions in College Station diagnoses and repairs the issue in a matter of days. Removing the need to source new parts from manufacturers, whilst recycling existing parts. Going some way in being environmentally responsible and saving money for you as a repair shop, and your customers.